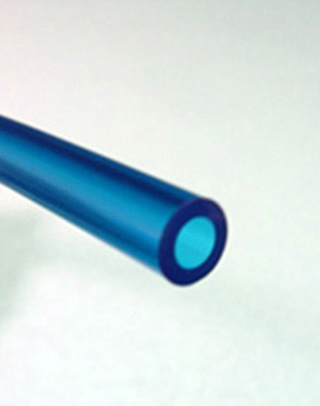

Soft TPE Tubing for Replacement of Latex, Silicone & PVC

Thermoplastic elastomer (TPE) possesses recyclability properties where you can reprocess scrap or reject parts. The material has a good compression set & chemical resistance but not at high or low temperatures. The material can also be formulated to be non-tacky, which helps repel dirt & other contaminants. Additional advantages include:

- Abrasion resistance

- Excellent color ability

- Good electrical properties

- Heat-sealable

- High elasticity

- High fatigue resistance

- High impact strength

- Low compression set

- Low density

- Low specific gravity

- Moderate UV resistance

- Resilient to chemicals & weathering

- Strong & flexible at room temperature

- Suitable for high-volume injection molding

- Two-shot molding options

- Various surface characteristics & properties

EXALT offers:

- Traditional USP Class VI Medical Grades

- DEHP-Free & Phthalate-Free Formulations

- ETO & Gamma Compatible

- Colored, Tinted, Striped & Frosted

- Cut to Length/Neat Packed

Sizes: ID’s & OD’s from .010"-.500", Custom Lengths

Materials: Styrenic Based Thermoplastic Elastomers (TPE) from Saint-Gobain – C-Flex®, Mexichem Specialty Compounds (AlphaGary) - Evoprene®, Kraton Polymers - Kraton, Teknor Apex – Medalist® & Monprene®, Exxon Mobile – Santoprene™, PolyOne – GLS™ Versaflex™ & Dynaflex™

Ask the Experts

*It is the customer, or device manufacturer's responsibility to ensure that any given tubing is suitable for its intended application. No warranties are given; All implied warranties of merchantability or fitness for particular purposes are expressly excluded.